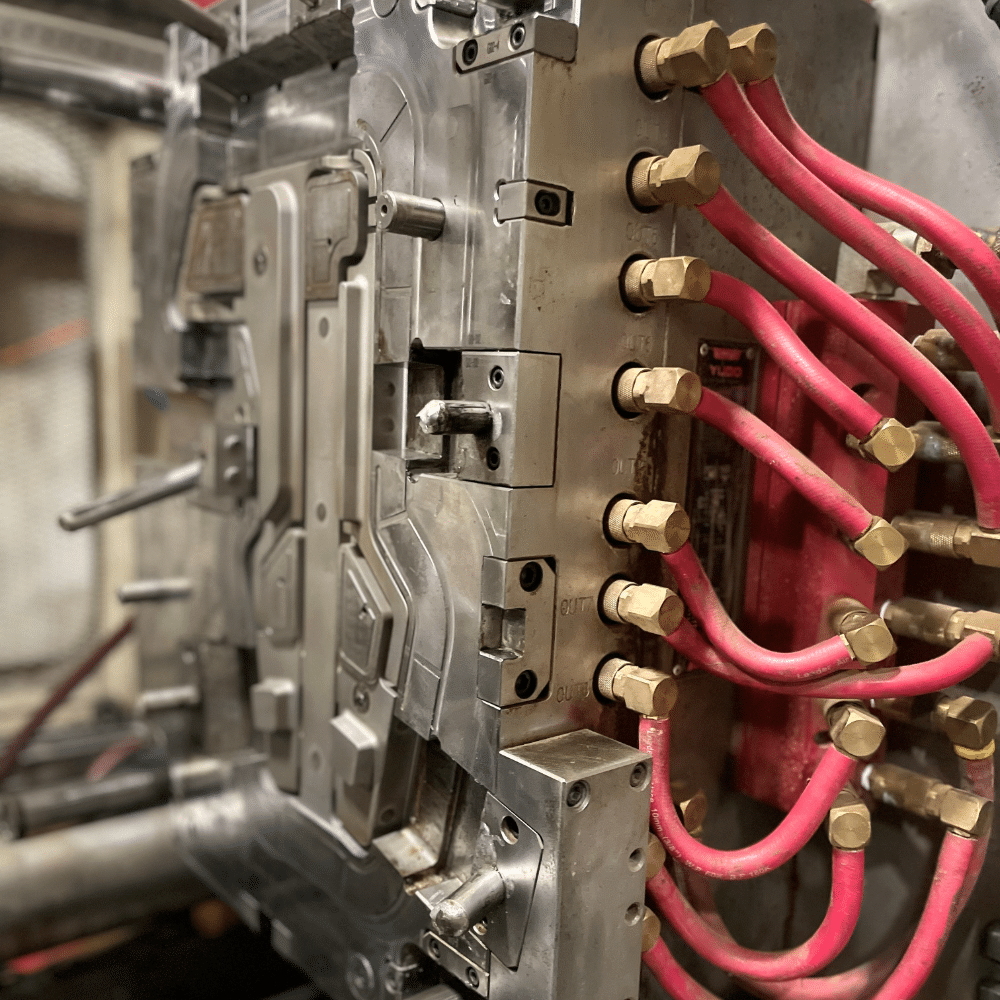

Molding

Tool Technology Corp’s injection molding service involves working with customer partners from concept through production. Our 30 years of industry experience and knowledge in manufacturing a wide range of plastic parts and products takes the stress and guesswork out of the design process and allows our professionals to design and optimize the best solution for our customers. Our approach is highly precise and efficient and can produce complex and intricate products with high accuracy and consistency. From tiny electronic parts to automotive assemblies and more, we do it all! Contact us today for more information.

Our molding services include

- Concept development

- Prototyping

- Product development

- Tool development

- Product production

Markets we work with

Consumer Recreational Vehicles

These customers require precise tolerances, competitive pricing, and large runs. The components must have strong UV protection and color hold. These often require secondary assembly processes including clips, rivets, fasteners, dampeners, etc.

Manufacturing Components

Manufacturing components require strong, wear resistant components and the ability to produce many variations with competitive pricing. We have made products for robots, sorting and applications.

Electronic Connectors

These customers require tight tolerances, color fastness and individual Quality Control inspections. They consist of multi-piece assemblies that require a snap fit. Consulting with customers allows for very tight tolerances and short cycle times that lower cost of production.

Consumer Packaging

Precise tolerances and color fastness are givens for this customer. Large quantity production runs utilizing our large presses makes for efficient, cost competitive deliverables. The ability to over mold and warehouse has helped customers even out their demands cycles.

Benefits of working with us

We are your partner in producing your product from concept to delivery. Our Molding team is responsive, efficient, collaborative, and customer focused. The Tool Technology Staff embodies the company culture solidified through 30+ years in the Tooling and Molding markets.